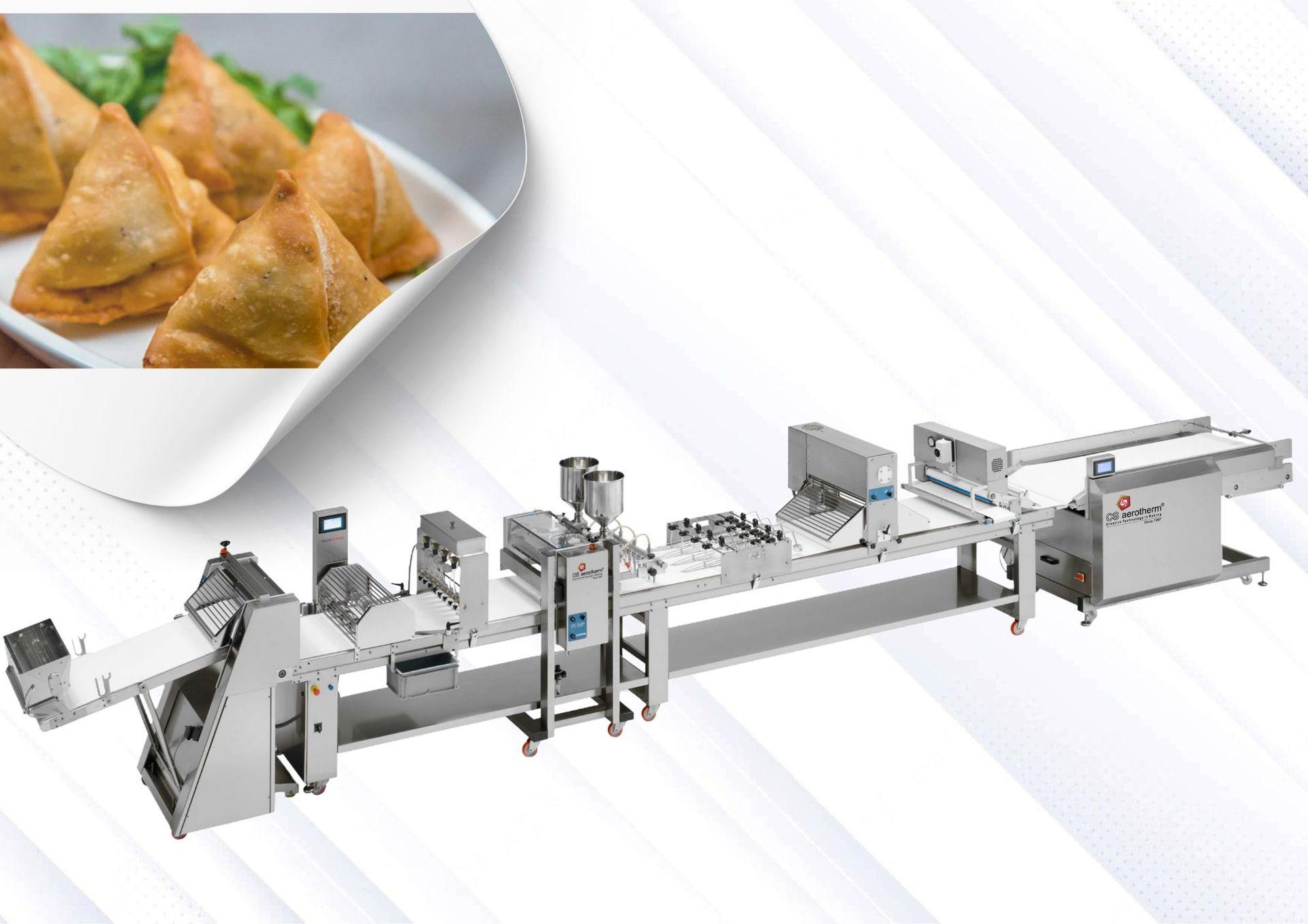

CS Lamination Line designed for precision and efficiency. At the heart of this process lies advanced machinery that meticulously layers and stretches dough to achieve uniform thickness and texture. Beginning with the mixing and kneading of high-quality ingredients, the dough is then fed through rollers that progressively thin it to the desired thickness. Next, the dough passes through a series of lamination rollers, where layers are precisely stacked and compressed to create the characteristic flakiness of samosa sheets. Temperature and humidity control throughout the line ensure consistent quality, while automated cutting mechanisms precisely shape the sheets before they are ready for packaging or further processing.

CS Samosa Line

This state-of-the-art production line not only meets rigorous food safety standards but also ensures that each samosa sheet maintains its integrity and freshness, ready to delight consumers with its crispy, golden perfection.

Key Features Includes:

Standard Specification Includes:

Details

|

Specifications

|

Model

| |

Production Capacity (Kgs / Hr)

| 7500 |

Length of the Machine (mm / inches)

|

4000 / 158 or 5000 / 197 or 6000 / 237

|

machine Height (mm / inches)

| 900/35.4 |

Belt Width (mm / inches)

|

650 / 26

|

Tray Sizes (L x W) in mm / inches

|

400 x 600 / 16 x 27 or 450 x 700 / 18 x 28

|

Installed Power (KW / HP)

|

6.5 / 8.7

|

Voltage and Phase (Volts / Phase / Hertz)

|

415 / 3 / 50

|

External Dimensions (L x W x H) in mm /inches

|

10700 x 1078 x 1637 / 422 x 43 x 65

|

Weight (Kgs)

|

1850

|