A Bread and Rusk Cooler is a specialized piece of equipment used in bakeries or food production facilities for the cooling process of freshly baked bread and rusks. Its primary function is to efficiently and effectively cool down the temperature of the baked goods after they come out of the oven.

The main purpose of the bread and rusk cooler is to rapidly reduce the temperature of freshly baked bread loaves or rusks as they exit the oven. This cooling process is crucial to stabilize the products and prevent over-baking or moisture loss, ensuring a desirable texture and quality.

Bread and Rusk Cooler is an essential component in bakery operations, providing an efficient and controlled cooling process for freshly baked bread and rusks. It helps maintain product quality, ensures consistency, and contributes to the overall efficiency of the baking production line.

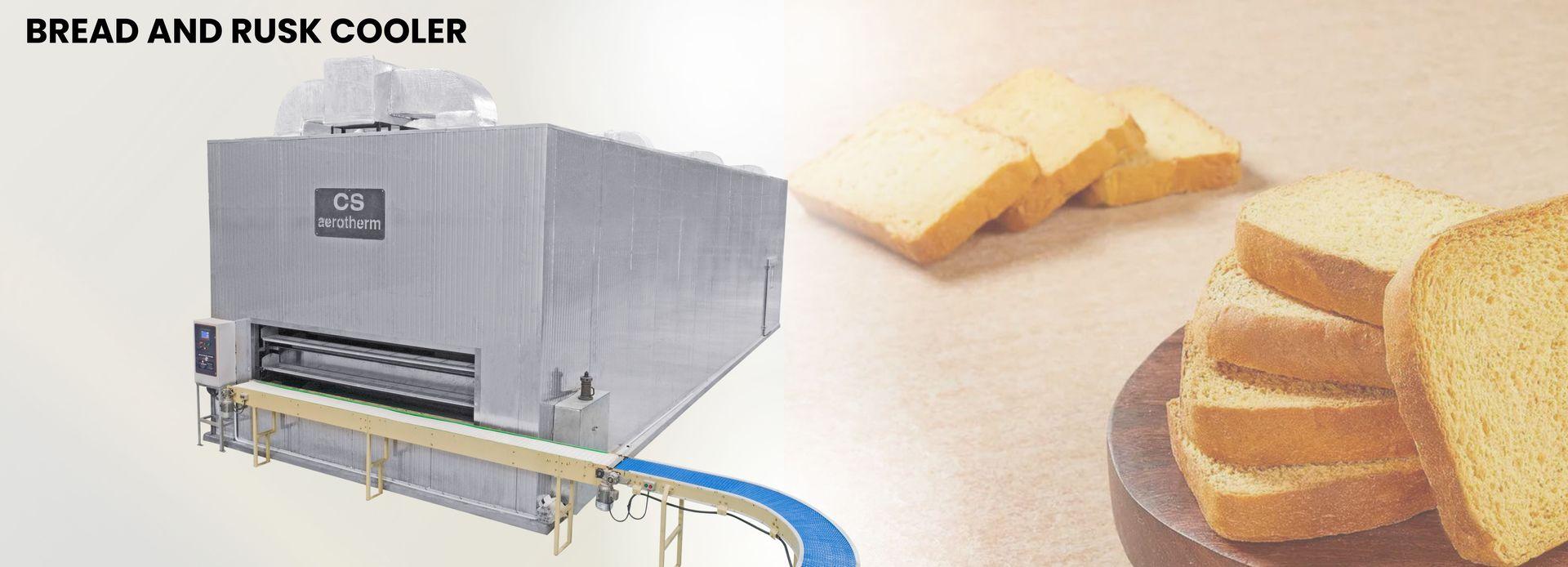

CS Bread and Rusk Coolers

Waiting for bread to cool down before you can slice it can be quite tiresome. Therefore, CS aerotherm brings to you our Bread Cooling system. After bread is removed from the moulds, it can be kept inside our Bread Cooling system where it’s passed through cold air. It fastens the entire process of cooling bread without compromising on the quality. Once the cooling process is complete, Bread is in perfect condition to be cut into slices.

Bread and Rusk Coolers

A bread and rusk cooler is an essential piece of equipment in the baking industry, designed to cool freshly baked bread and rusks efficiently and uniformly. Proper cooling is crucial for maintaining the quality, texture, and shelf life of baked goods.

Cooler Specifications

Specifications can be changed as per your needs.

Details | Specifications |

Minimum Temperature (°C / °F) | 25 / 77 |

Time needed for Cooling (Hrs) | 4 |