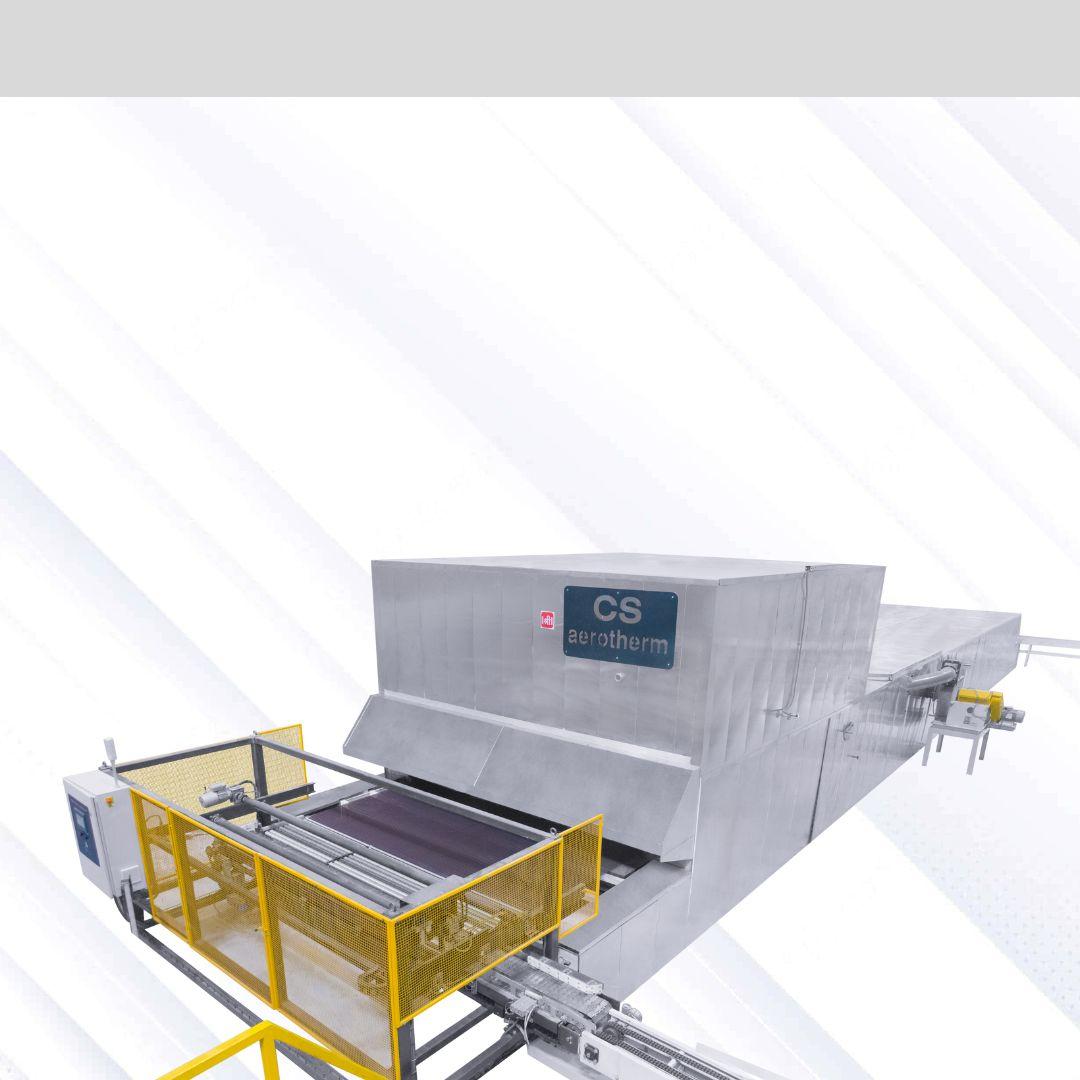

The Mould Loading System from CS aerotherm is a sophisticated solution designed to enhance the efficiency and precision of the moulding process in various industries. where consistent and accurate mould loading is crucial for high-quality production.

The Mould Loading System is designed to automate the loading process, significantly reducing manual labor and increasing operational efficiency. This automation leads to faster production cycles and consistent output quality.

Mould Loading System

In continuation to the automatic mould loader for tunnel oven, we are pleased to introduce automatic mould unloader for tunnel oven. It works on similar principle and components that are required in a mould loader. Once baking is done, moulds are transferred onto a roller conveyor. A beam sensor activates this roller conveyor. It ensures a safety passage of moulds coming out from the tunnel oven.

CS Loading system

The loading system in a production environment, particularly in baking and cookie manufacturing, is a crucial component that ensures the smooth transfer of products from one stage of the production process to another.

Specifications of Mould Loading System

(This can be customised to suit your needs)

Details | Specifications |

Charging Width (m) | 3 |

Conveyor Length(m) | 4 |

Conveyor Speed (m/s) | 0.27 |

Conveyor Power (KW / HP) | 0.37 / 0.49 |

Voltage and Phase (Volts / Phase / Hertz) | 415 / 3 / 50 |

Pushing Device Stroke Length (mm) | 890 |

Pushing Device Speed (m/s) | 0.21 |

Compressed Air needed (bar) | 6 |

Weight (Kgs) | 1100 |

Mould Unloading System

In continuation to the automatic mould loader for tunnel oven, we are pleased to introduce automatic mould unloader for tunnel oven. It works on similar principle and components that are required in a mould loader. Once baking is done, moulds are transferred onto a roller conveyor. A beam sensor activates this roller conveyor. It ensures a safety passage of moulds coming out from the tunnel oven.

Specifications of Mould Unloading System

(This can be customised to suit your needs)

| Details | Specifications |

Charging Width (m) | 3 |

Conveyor Length(m) | 1.3 |

Conveyor Speed (m/s) | 0.27 |

Conveyor Power (KW / HP) | 0.75 / 1.00 |

Voltage and Phase (Volts / Phase / Hertz) | 415 / 3 / 50 |

Duplex Chain Conveyor (m x mm) | 3 x 400 |

Pushing Device Speed (m/s) | 0.21 |

Compressed Air needed (bar) | 6 |

Weight (Kgs) | 1220 |