Millie's Cookies Line emphasizes the high-quality and indulgent nature of the cookies enhanced by the lamination process, suggesting a superior and more enjoyable product.

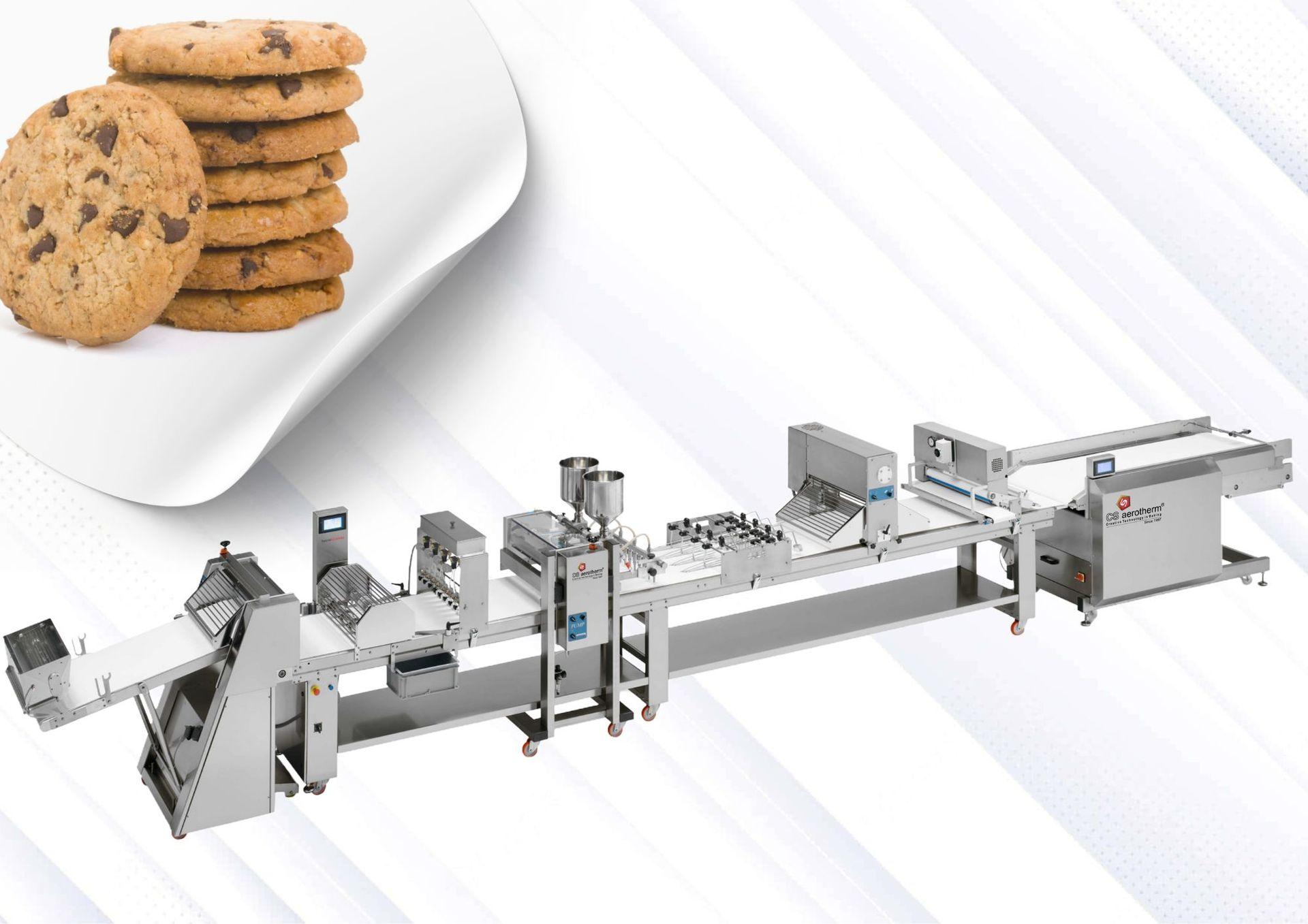

A Millie's cookies lamination line is an advanced and efficient manufacturing setup designed to produce high-quality laminated cookies with consistent texture and taste. This specialized production line combines cutting-edge technology with precision engineering to create multiple layers of dough and filling, resulting in cookies that have a unique, flaky, and rich texture.

CS Millet Cookies Line

Investing in a cookies lamination line represents a significant step towards modernizing and scaling up cookie production.

The laminated dough is rolled to the desired thickness, maintaining consistency across the entire batch.

Advanced cutting tools shape the cookies into uniform sizes and shapes, ensuring that each cookie meets the desired specifications.

Key Features Includes:

Standard Specification Includes:

Details

|

Specifications

|

Model

| |

Production Capacity (Kgs / Hr)

| 750 |

Length of the Machine (mm / inches)

|

4000 / 158 or 5000 / 197 or 6000 / 237

|

machine Height (mm / inches)

| 900/35.4 |

Belt Width (mm / inches)

|

650 / 26

|

Tray Sizes (L x W) in mm / inches |

400 x 600 / 16 x 27 or 450 x 700 / 18 x 28

|

Installed Power (KW / HP) |

6.5 / 8.7

|

Voltage and Phase (Volts / Phase / Hertz) |

415 / 3 / 50

|

External Dimensions (L x W x H) in mm /inches

|

10700 x 1078 x 1637 / 422 x 43 x 65

|

Weight (Kgs)

|

1850

|